Formula SAE

- Category: Machining

- Project date: May 2022 - May 2023

- Project URL: Matador Motorsports

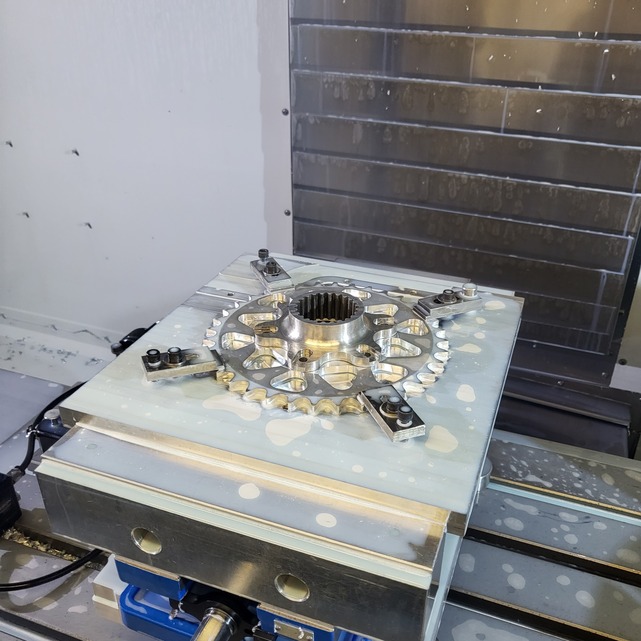

Rear Sprocket and Fitment Check on Powerhub

To manufacture the inside of the sprocket, I employed a ½ inch end mill to cut out each pocket and shape the interior. Additionally, I addressed the flatness issues by facing the center of the sprocket, ensuring a smooth and even surface. To achieve a refined finish on the pocket interiors, I utilized a ¼ inch end mill for the final pass. This allowed me to achieve precise dimensions and a polished appearance within each pocket. By carefully selecting the appropriate end mills and executing each machining operation with precision, I successfully created the intricate and accurately sized inside of the sprocket. The combination of the ½ inch and ¼ inch end mills enabled me to accomplish the desired outcome and deliver a high-quality product.