Formula SAE

- Category: Machining

- Project date: May 2022 - May 2023

- Project URL: Matador Motorsports

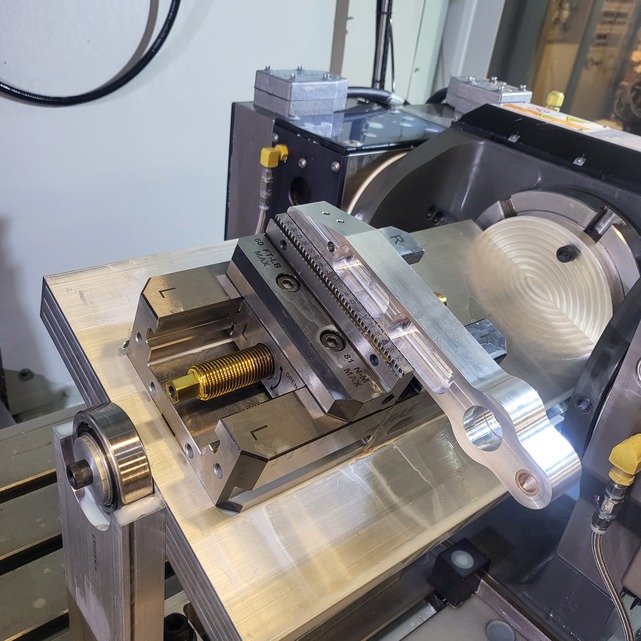

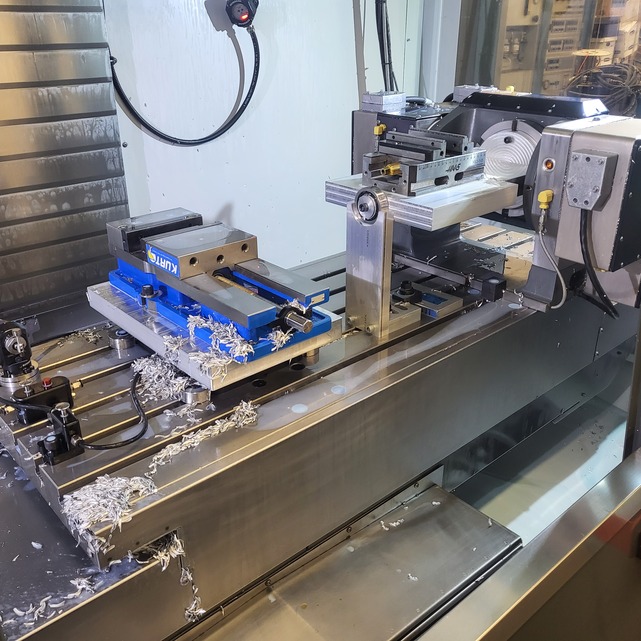

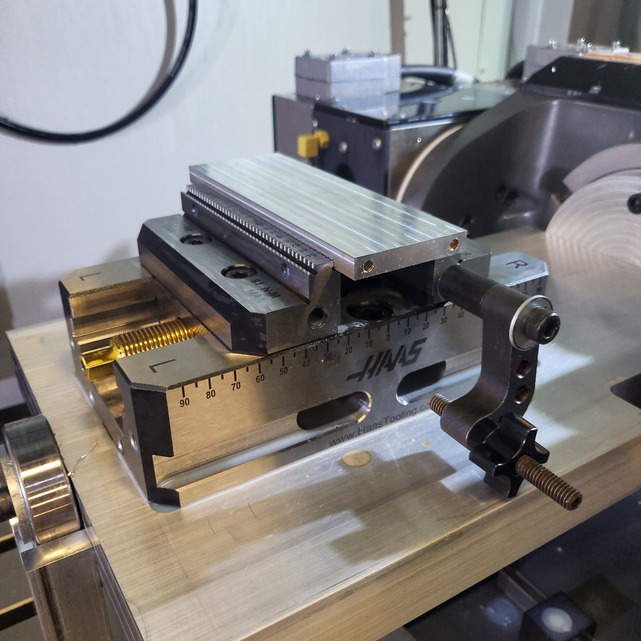

Fourth Axis Workholding with TR200Y

The fourth axis workholding was a design created to solve the need for machining parts that required access to multiple sides. We had an HAAS HRT210 in the lab; however, we did not want to take out the HAAS TR200Y since we still needed it for 3+2 machining. To avoid the problem, we used a pierson pro pallet to hold the HAAS self-centering vise. I machined the round part on the end with a nub to fit in the HAAS TR200Y. I bolted the round part to the pallet with two 3/8-16 bolts and used two T-slot nuts and two 3/8-16 bolts for mounting to the TR200Y. After we used a bearing and a machined support to help with rotating the pallet. We left 0.01 of play in the bearing in order to allow us to align the B-Axis with a dial indicator. The fourth axis workholding allowed me to make the engine wedges to help position the engine in the chassis jig table, the pedal assembly with the angled holes, and the differential bar plates.