Formula SAE

- Category: Machining

- Project date: May 2022 - May 2023

- Project URL: Matador Motorsports

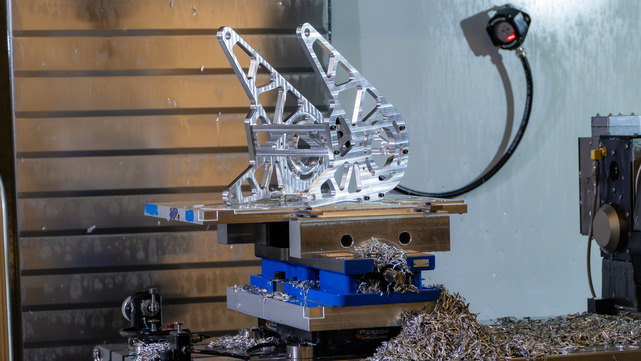

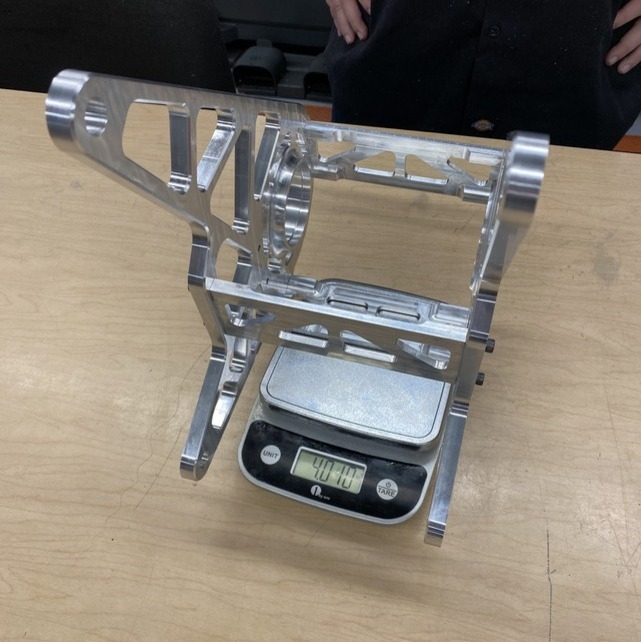

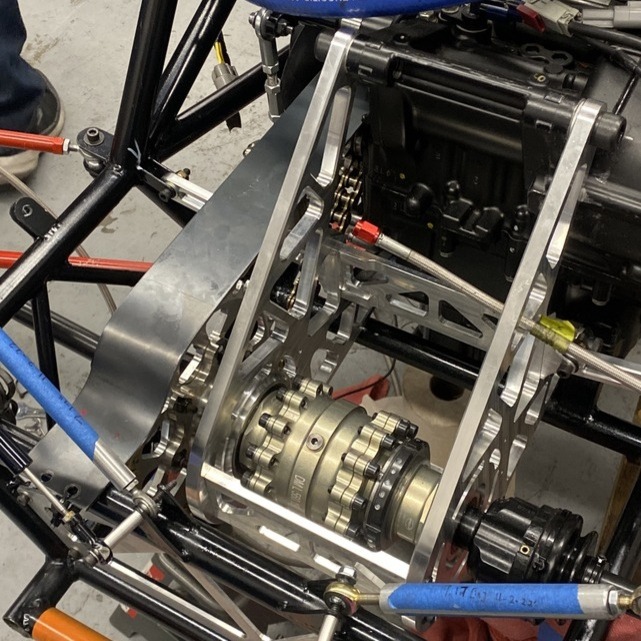

Drivetrain - Differential Cage

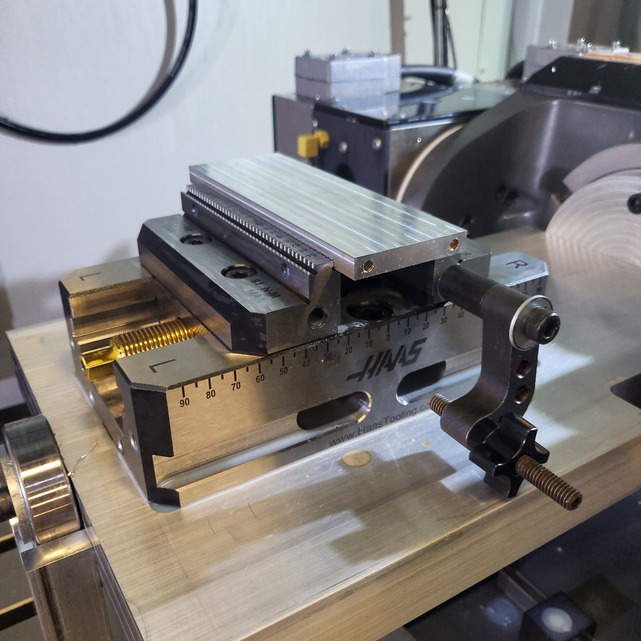

The drivetrain cage was an iteration from the 2021-2022 team. Their design involved mounting the cage to the chassis and engine. Mounting to the chassis caused problems that the 2023 team needed to address. My teammate, Matthew Awad, worked on the CAD model and figuring out how to position the new differential cage. Once he finished the CAD modeling, I began the CAM analysis. To begin, I created a fixture plate in order to place my stock on top. I drilled four holes on the stock to secure the plate to the fixture that I had drilled and tapped before. We didn't want to take a long time to manufacture each plate so we ordered a ¾ inch end mill to do a large amount of the cutting. One thing to be careful with is the forces that the ¾ inch end mill has. It was strong enough that it pulled the fixture plate out of the jaws. It almost ruined the part but we were able to move the stock in order to save the stock. I modified the fixture plate and the 10in aluminum jaws to incorporate four clamps that prevented the fixture plate from coming out. I finished facing the stock and creating each inner pocket. The bearing hole was machined with the ½ inch end mill and then ran a finish pass to get the correct fitment on the bearing. I had to do a couple finish passes till the bearing fit had transitional fit. A ½ inch ball end mill was used for the bearing lip. After the internal features were finished, I bolted the side plate using the bolt holes in the differential cage in order to do the contour pass for the outside.